EIT RawMaterials Backed Startup Fibrecoat Named to Time’s Best Inventions 2025

From the university lab to TIME Magazine’s Best Inventions list, FibreCoat’s radar-absorbing material is reshaping Europe’s defence and aerospace sectors.

FibreCoat, supported by EIT RawMaterials in 2021, has been recognised by TIME Magazine as one of the Best Inventions of 2025. Its breakthrough Radar Absorbing Material (RAM) combines metal-coated fibres with plastics to create lightweight, customisable composites that can make aircraft and other objects undetectable by radar.

It’s a great honour to be part of that list. When I look at the other inventions featured, major innovations like Anthropic Claude Sonnet 4 and Nvidia DGX Spark, it feels incredible to see our name among them. As a small materials startup working in a niche field, this recognition gives us valuable visibility and might connect us with customers we hadn’t anticipated. It’s also a huge success for our team. Everyone feels proud and energised as we head toward the end of the year.

Robert Bruell, CEO and Co-founder of Fibrecoat

A story of persistence and reinvention

FibreCoat spun out from Aachen University, but its story began in 2014, when the idea emerged to make fibre-reinforced plastics more affordable by coating polymers onto glass fibres that could be directly processed into finished products. Together with co-founder Alexander Lüking, the team advanced the concept from a laboratory idea to pilot scale. By 2018, the technology was performing well, yet progress in the industry remained slow. After witnessing how companies often acquired university innovations only to shelve them rather than industrialise them, the founders decided to take matters into their own hands. In 2020, supported by Germany’s EXIST grant and joined by a third co-founder, Richard Haas, they officially launched FibreCoat.

The company’s journey soon faced major challenges. The COVID-19 pandemic halted polymer research as chemists were unable to work remotely, and key materials became increasingly difficult to source. This prompted FibreCoat to pivot toward metal coating. When the war in Ukraine drove energy prices sharply upward in Germany, the team swiftly moved production to Georgia. In 2023, FibreCoat secured its first major order, around 50 tonnes, and continued scaling. By the end of 2024, the company had raised an additional €20 million to expand its production capacity within the defence sector. Today, FibreCoat credits its growth to a strong, adaptable team and what the founders describe as a form of “smart naivety”: a firm belief in their mission, paired with the willingness to listen and adapt as the world evolves.

The support of EIT RawMaterials Booster Programme

In 2021, the company was in a foggy phase. The support from EIT RawMaterials helped bridge a dry period between investments and provided the opportunity to explore new markets and networks. The materials sector is a small, tight-knit community, and having access to it proved invaluable.

As a first-time founder, the team often received advice from incubators designed for software or consumer startups, which did not always apply to the materials industry. Unlike software, where scaling to thousands of users is key, the materials world focuses on working with a limited number of customers initially and producing materials by the tonne. EIT RawMaterials played a crucial role by connecting the company with investors who understand deep tech and materials, offering valuable feedback, and helping navigate the unique challenges of fundraising in this sector.

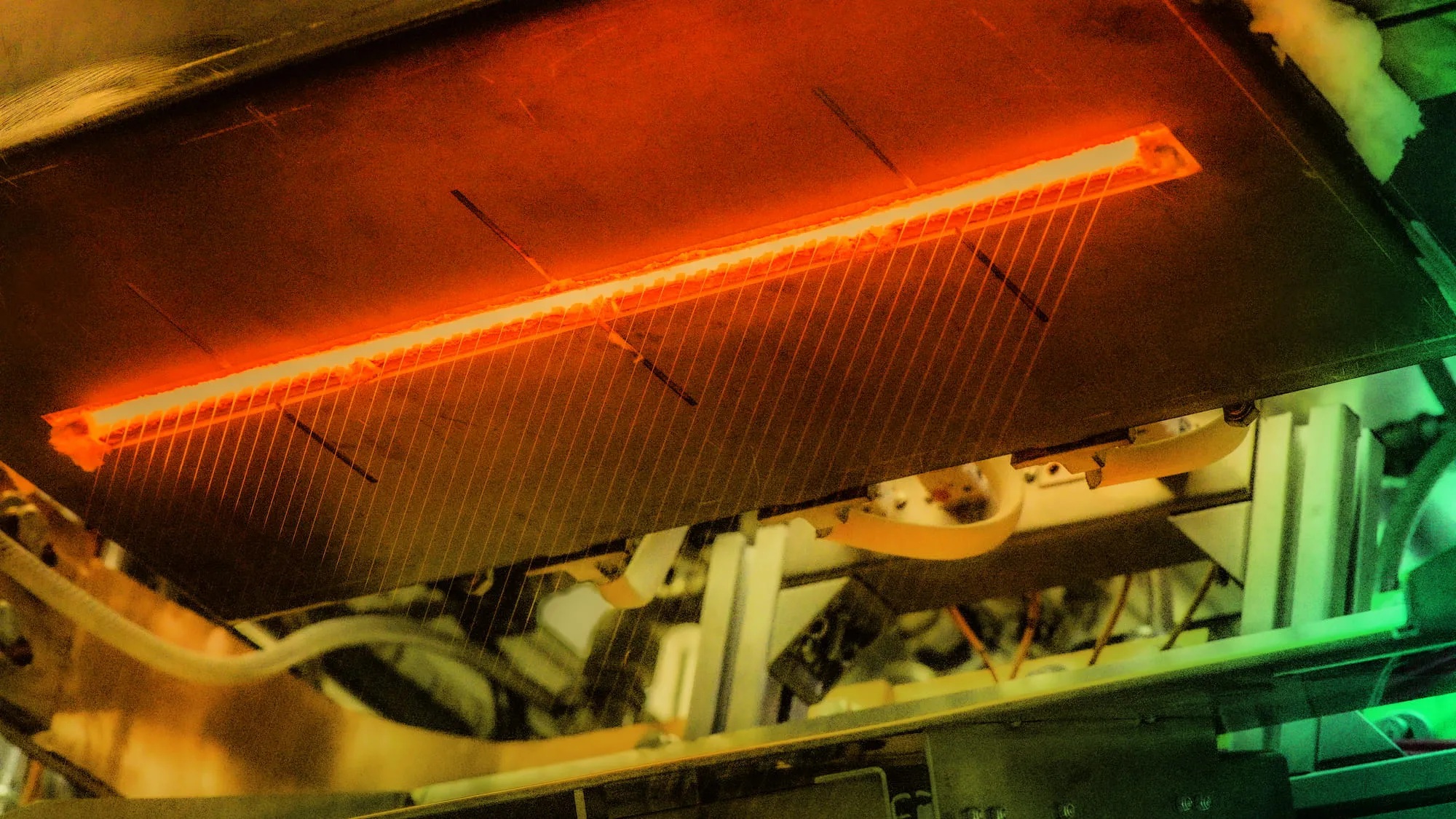

FibreCoat’s Radar-Absorbing Material

FibreCoat’s radar-absorbing materials are designed to shield fighter jets, drones, and satellites from radar detection. Unlike traditional solutions, which often rely on bulky foams or paints that degrade over time and require frequent reapplication, FibreCoat’s technology offers a more sustainable and cost-effective alternative. By combining coated fibres with plastics, the company produces lightweight, high-performance plates capable of absorbing a much broader range of radar frequencies than conventional materials. The design can be fully customised according to the specific application, radar type, or radiation requirements, providing tailored protection for advanced defence and space systems.

Driving Europe’s Raw Material Independence

FibreCoat is helping to reduce Europe’s dependency on imported raw materials by developing high-performance solutions tailored to the defence and space sectors. Its AluCoat product, for example, combines the strength of glass with the conductivity of aluminium to create advanced materials from resources available in Europe. By building its own production lines, FibreCoat enables local manufacturing for partners, ensuring control over production and protection from global supply chain disruptions.

Looking ahead, the company is expanding its product portfolio for defence, including projects supporting NATO and Ukraine, while also advancing in the space sector with radiation-absorbing materials set to fly on a satellite next year. Through strategic scaling and innovation, FibreCoat aims to bring more European-made materials to both defence and civilian markets.

Share this page

Share this page